Since January 2019, the Canadian Food Inspection Agency (CFIA) has been enforcing new food regulations across all food commodities. A key requirement of the new regulations is the validation of Critical Control Points (e.g., cooking, chilling, etc.) and key pre-requisite programs (e.g., sanitation, allergens, positive air pressure in RTE areas, etc.)

What is HACCP System Validation?

Validation is a process that focuses on the collection and evaluation of scientific, technical and observational information to determine whether a control measure or combination of control measures is capable of achieving their specified purpose in terms of hazard control when subjected to worst-case-scenario conditions.

Why is HACCP System Validation Important?

The main goal of validation is to ensure that the HACCP system continues to deliver safe food products and thereby meet regulatory requirements. This means that controls measures need to be re-evaluated to ensure all food safety parameters can be delivered consistently by both the equipment as well as current processing conditions. HACCP System validation has many benefits, some examples include:

- Providing a higher level of assurance to consumers and clients;

- Avoiding regulatory interruptions (CFIA CARs);

- Building confidence from having a well-controlled process.

Considerations For Determining ‘Worst-Case-Scenario’:

The determination of an adequate ‘worst-case-scenario’ is essential to demonstrate that the HACCP system remains effective, even under the most challenging processing conditions. Some considerations for ‘worst-case-scenario’ include:

- Processing conditions in peak production periods add stress on equipment;

- Product size and characteristics influence overall process lethality (e.g., use of anti-microbial agents);

- Critical processes could be adversely influenced by seasonal changes (e.g., chillers during warmer summer months);

- Emerging validated scientific data is found equivalent to existing regulatory performance standards.

General Considerations To Conduct HACCP System Validation:

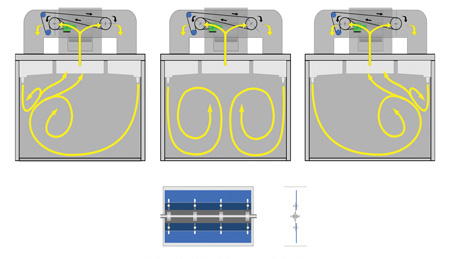

The validation process involves the collection and analysis of process data that is critical to producing safe food products. As such, high accuracy instruments are required to produce reliable and repeatable results. Given that equipment and processing conditions may fluctuate from batch to batch, oftentimes it is recommended that more than one batch be evaluated, to determine the degree of variability between batches. Statistical software such as Minitab is also useful to map out a variation within a process.

Let our extensive backgrounds and experience in high-risk processes help you manage all of your food safety validation needs. Our services include, but are not limited to:

- Cooking (smokehouse cold-spot evaluation);

- Cooling/chilling, alternative cooling procedures (e.g., meat and poultry);

- Uncooked, dry-cured / fermented meat products (e.g. salami);

- Regulatory representation (CFIA, FSIS)