Calibration

Quantum Food Solutions

Proper equipment calibration has an important role in food safety. When the equipment controlling physical, chemical or biological hazards in the food operation is off even a little, it could ruin your product or put the consumer at risk. Calibration ensures that all equipment entrusted to monitor food processing performs as intended, with accuracy and consistency.

Quantum Food Solutions takes this role as seriously as you do. Our equipment calibration and consultancy services will make sure that every measurement remains within specification to keep your products safe!

Equipment Calibration Is Key To Business Success

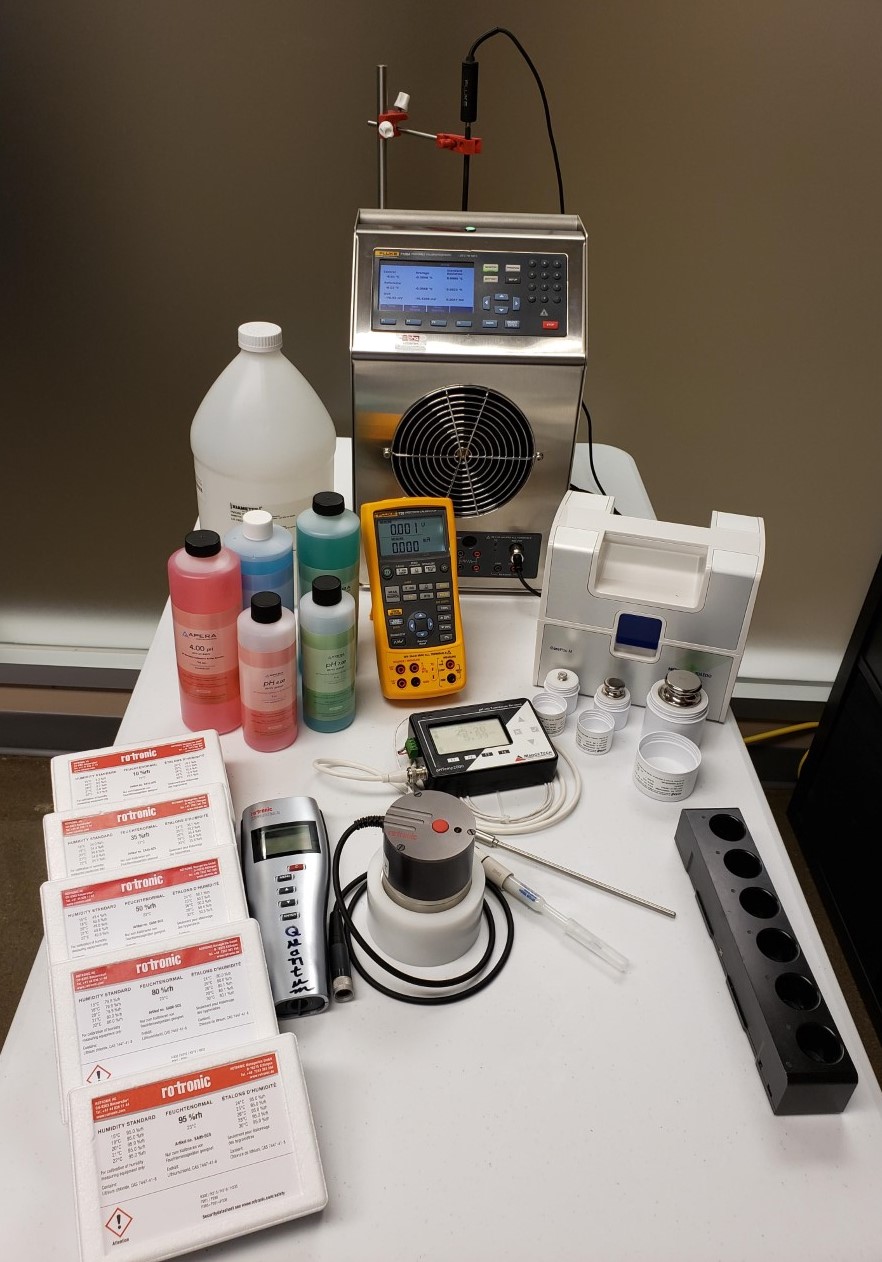

Equipment calibration is an integral part of running an effective HACCP system. Many critical control points and process controls are required to undergo on-going calibration. The food and beverage industries use many different process controls, including:

- Temperature devices to monitor thermal processes such as cooking and pasteurizing, hot holding, cooling and chilling, defrosting and thawing, freezing

- Infrared temperature devices for monitoring product and persons

- pH meters to monitor fermentation in dry-cured meats, low-acid, and acidified products

- Water Activity meters (Aw) to monitor ageing in dry-cured and fermented meats

- Weight scales to ensure regulated limits of additives and other anti-microbial agents are respected

The Quantum Food Solutions Advantage

Quantum Food Solutions' calibration compares the measurements taken by a test instrument or consensus standard/s against those taken by your own equipment. Our services come with five guarantees:

Throughput: Our equipment is designed to calibrate multiple units simultaneously. This significantly reduces ongoing calibration costs.

Service Delivery: We conduct all calibrations on-site, with portable equipment that allows for calibrations on platforms and other hard-to-reach plant areas. Certificates of Calibration (NIST) are issued the same day.

On-site Support: You may temporarily use our high-accuracy equipment at no cost while your devices are being calibrated. This reduces downtime while we complete our work.

Calibrated Accuracy: +/- 0.01 °C, providing a much higher than 4:1 test uncertainty ratio (TUR) for most critical applications.

Operational Range: –200 °C to 661 °C for most temperature devices, data loggers, thermocouples, RTDs, etc.

Quantum Food Solutions' Calibration Technicians look forward to discussing how our services can be customized to meet the unique needs of your operation. Please contact us for a free consultation.

Food Safety Validation

Quantum Food Solutions

The process of validation can be defined as a scientific approach aimed to demonstrate that food safety controls (i.e., Critical Control Points and critical-to-food-safety pre-requisite programs) are effective and consistently result in a safe food product. Under the new Canadian food regulations (SFCRs), food safety validation is considered just as equally important, if not more, than just having a fully implemented Preventative Control Program (e.g., HACCP program).

Since validation is a multi-layered process, CFIA has provided industry with guidelines covering expectations (click here). These expectations were derived from the Codex-Alimentarius International Food Standards (Reference document CAC/GL 69-2008).

Adequate safety controls for fully-cooked, ready-to-eat food products include the proper identification of cold-zones, probe malfunction and other 'in-plant' factors. Examples include: hams, sausages, chicken nuggets, frozen pizzas and more.

This category includes foods which do not have a kill step and/or ready-to-eat refrigerated food. Foods in this category are considered "fresh".

Fermenting and drying are probably the oldest forms of meat preservation. We are able to ensure that this old process meets today's level of compliance.

Arguably one of the most important aspects of your food safety program is sanitation. Keeping things clean is a must in order to protect against the biological, chemical and physical contamination of your products.

It is important to keep everything clean even the things we cannot see. Maintaining clean air and disinfecting high traffic areas is essential to success in the food processing industry.

Various foods contain components that can cause life threatening reactions for people with food allergies. In order to avoid costly recalls all allergens must be properly controlled.

Testimonials