Allergens

Validation

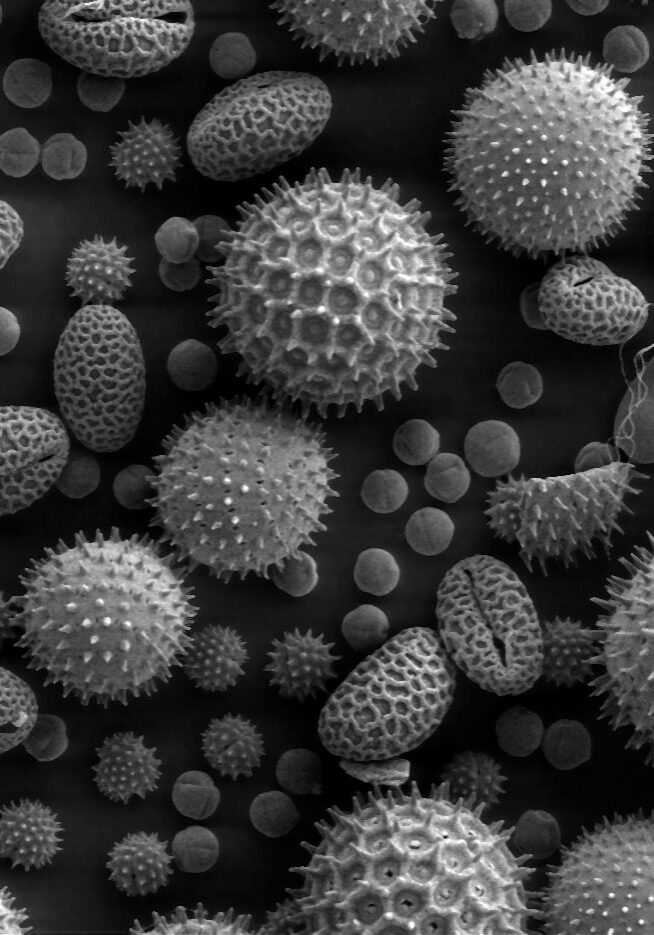

Many different foods and ingredients can cause life-threatening reactions in individuals with food sensitivities. Allergens, including peanuts, treenuts and some naturally occurring substances including sulphites and gluten are considered high-risk chemical hazards. As such, food processing facilities must consider their handling during their hazard analysis and when establishing preventive control measures.

Quantum Food Solutions can help you develop and maintain handling and hazard plans that prevent the possibility of cross-contamination. Our safety consultancy services will identify weaknesses and make sure your products stay safe!

How Cross-Contamination Can Happen

If handling or processing standards are not in place or followed, allergens can easily contaminate ingredients, products in process, and finished food products. Common allergens like dry milk, sesame and gluten can travel through the air and get on high-touch surfaces, too. The most common ways undeclared allergens enter food products are:

- Ingredients are transported in incompatible loads (allergens with non-allergens nearby)

- Cross-contamination of an ingredient with an allergen before or after it is received at the facility

- Accidentally adding allergens to products that do not usually contain them

- Mislabelling of ingredients and finished products (label omits subcomponent that is an allergen)

- Improper sanitation during product changeovers

- Improper storage practices (allergens are stored above non-allergens)

- Cross-contamination from a different production line

Cross-contamination is one of the most likely sources of allergen contamination. It can come from improper hygiene like sub-par handwashing procedures, dirty sleeves, soiled coats and other Personal Protective Equipment. It can even occur through something as small as an employee not washing their hands after finishing their lunch.

It can also occur when receiving ingredient shipments in bulk, or during storage which is why it is important to have the proper documentation in place for traceability.

Quantum Food Solutions Food Safety Validation

To minimize this risk, a tight allergen program and safety validation must be put in place. Quantum Food Solution's team of food safety consultants have the knowledge and skills to implement an effective allergen program in your facility. Call or email us today for a free consultation, and we'll help make your facility and the work process safe for all.

Preventing Cross-Contamination In Your Food Processing Facility

Undeclared allergens, gluten and added sulphites are a leading cause of food recall in Canada. Preventing cross-contamination in a food processing facility starts with identifying the allergens that enter the facility. In Canada, the most common food allergies and related disorders are:

- Peanuts and tree nuts like almonds, Brazil nuts, cashews, hazelnuts, macadamia nuts, pecans, pine nuts, pistachio nuts and walnuts

- Sesame

- Milk and dairy

- Eggs

- Seafood like fish, crustaceans and molluscs

- Soy

- Wheat gluten and triticale

- Mustard

- Sulphites

The presence of allergens, gluten and added sulphites cannot be eliminated or reduced by thermal treatment or any post-processing steps. Preventive control measures are essential during the preparation steps to stop any allergens from contaminating food in which they are not an intentional ingredient.

Correctly declaring ingredients on the food label is necessary to notify consumers that may be sensitive to a food allergen, gluten or added sulphites, so they can avoid that product.

Contact

Submit Your Inquiry

Testimonials