What is Thermal Validation or Cold Spot Evaluation?

Within the context of manufacturing safe cooked products, thermal validation, which is commonly known as cold spot evaluation refers to the measurement of the maximum thermal differential within a cooking vessel. Examples include forced-convection ovens or smokehouses (i.e., batch and continuous), impingement ovens, among other oven types.

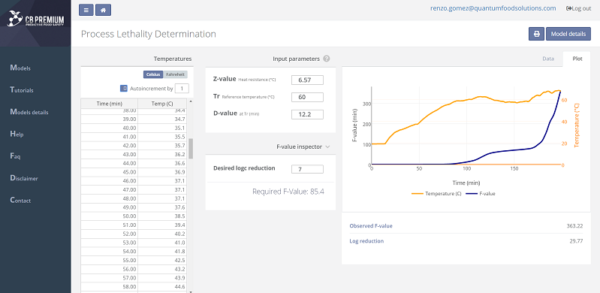

The main purpose of cold spot evaluation is to ensure that all pieces of product inside a cooking vessel receive adequate thermal treatment. Adequate thermal treatment is one that is lethal to the most heat resistant pathogens of public concern (e.g. mainly Salmonella spp., Listeria mono and E. coli O157: H7), under worst-case-scenario conditions.

How are cold spots, or cold zones formed?

With so many different types of cooking systems being used in industry, cold spots are can be formed for a variety of reasons. However, the most common factors leading to cold spot formation include, but are not limited to:

- Improper loading practices (i.e., ‘touchers’ scattered throughout smokehouse)

- Inconsistent loading practice (i.e., partial vs. fully-loaded smokehouse)

- Critical probes go out of calibration (i.e., product, dry-bulb and wet-bulb)

- Dampers go out of alignment causing a large variation in air velocity and temperature from side to side of the oven

- Critical components such as burners are unable to generate sufficient thermal capacity (i.e., not designed for purpose, or component failure)

Can cold spot evaluation be conducted in an empty oven (i.e., oven with no product inside)?

No. By current regulatory requirements, establishments are responsible to take into account: “Worst case scenarios […], specifically, the coldest spot of both the equipment and the product.” (2)

Are any establishments producing high-risk products exempt from cold spot evaluation?

No. For instance, the Canadian Food Inspection Agency (CFIA) has listed cold spot evaluation as a requirement in the current federal regulations (e.g., meat regulations: MHMOP, Chapter 4, Section 4.4.1) (2)

No. For instance, the Canadian Food Inspection Agency (CFIA) has listed cold spot evaluation as a requirement in the current federal regulations (e.g., meat regulations: MHMOP, Chapter 4, Section 4.4.1) (2)

In addition, as of January 2019, this requirement will be enforced across all establishments producing high-risk cooked products across Canada(1).

How many probes are needed for an adequate representation of the cooking process?

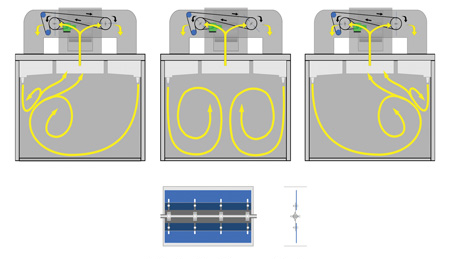

By best industry practice, a heat penetration study must be able to produce a 3-dimensional model of the heat distribution and thermal differentials in an oven / smokehouse as follows:

- Front to back,

- Top to bottom, and,

- Side to side

The heat penetration study must also be able to verify critical temperature probes (i.e., dry-bulb, wet-bulb, product).

Frequently Asked Questions About Thermal Validation

Zone in an oven that receives the least amount of heat, which sometimes can lead to under processed / undercooked food products.

This will depend on product size, and other factors such as anti-microbials present in the formula. The safest way to chill food is to keep it out of the 'danger zone', which is the temperature range where most microbes multiply under optimal temperature conditions. In particular the cooling time from 54 degrees Celsius to 27 degrees Celsius should not exceed 2 hours. Adding nitrites can make it safer, however, people think that nitrites are carcinogenic, even though these dissipate during the cooking process.

For frozen products is usually maximum - 18 C; for refrigerated products it is from 0C to 4C...in some countries it can go up as high as 5C. Most pathogenic growth begins very close to 7C.