What is HACCP System Validation?

HACCP system validation should be at the forefront of every food processing and manufacturing companies agenda. But for some practitioners this is easier said than done and must extend beyond the memorization of acronyms and workflows. In order to successfully execute an effective HACCP policy, leadership must be dedicated to in house education and proper HACCP strategy. A certified and responsive management team should be easily able to communicate an understanding of the advantages and resources needed to implement HACCP. It also requires ongoing staff preparation and learning. In addition to improved food safety compliance, companies can easily benefit from a better use of resources and prompt response to concerns.

Understanding HACCP and System Validation

Hazard Analysis Critical Control Points (HACCP) is the international standard of rapidly identifying unsafe conditions and managing food safety risks meant for implementation within a custom corporate food safety plan. A well-designed food safety plan with HACCP at the core helps businesses communicate and comply with product assurance and regulatory requirements in the regions they operate. Many governments across the globe are enacting legislation aimed at increasing food safety standards via stringent food regulations across all food commodities. For instance, a key requirement of new Canadian regulations enforced by Canadian Food Inspection Agency (CFIA) is the validation of Critical Control Points (e.g., cooking, chilling, etc.) and key prerequisite programs (e.g., sanitation, allergens, positive air pressure in RTE areas, etc.). But how do we implement proper system validation?

Why is HACCP System Validation Important?

Validation is a process that focuses on the collection and evaluation of scientific, technical and observational information to determine whether a control measure or combination of control measures are capable of achieving their specified purpose in terms of hazard control, when subjected to worst-case-scenario conditions.

The determination of an adequate 'worst-case-scenario' is essential to demonstrate that the HACCP system remains effective, even under the most challenging processing conditions. Some considerations for 'worst-case-scenario' include:

- Processing conditions in peak production periods add stress on equipment;

- Product size and characteristics influence overall process lethality (e.g., use of anti-microbial agents);

- Critical processes could be adversely influenced by seasonal changes (e.g., chillers during warmer summer months);

- Emerging validated scientific data is found equivalent to existing regulatory performance standards.

Considerations For Determining A 'Worst-Case-Scenario'

The determination of an adequate 'worst-case-scenario' is essential to demonstrate that the HACCP system remains effective, even under the most challenging processing conditions. Some considerations for 'worst-case-scenario' include:

- Processing conditions in peak production periods add stress on equipment;

- Product size and characteristics influence overall process lethality (e.g., use of anti-microbial agents);

- Critical processes could be adversely influenced by seasonal changes (e.g., chillers during warmer summer months);

- Emerging validated scientific data is found equivalent to existing regulatory performance standards.

General Considerations To Conduct HACCP System Validation

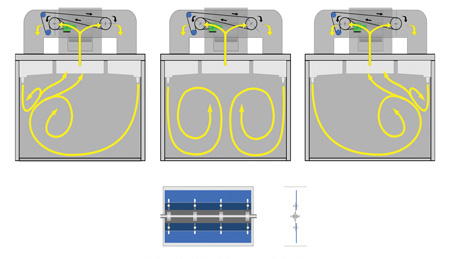

The validation process involves the collection and analysis of process data that is critical to producing safe food products. As such, high accuracy instruments are required to produce reliable and repeatable results. Given that equipment and processing conditions may fluctuate from batch to batch, oftentimes it is recommended that more than one batch be evaluated, to determine the degree of variability between batches. Statistical software such as Minitab is also useful to map out a variation within a process.

Frequently Asked Questions About HACCP System Validation

In terms of HACCP and modern food safety planning verification is centred on executing a safe and complaint in-house plan. The consistency and accuracy of that plan is the validation component. They are not mutually exclusive and an organization's compliance with the law depends on both aspects working together.

All employees of a business that deals in food processing, manufacturing and handling should be familiar with the regional food safety laws. They should also be trained on HACCP and know what their organization is doing to implement proper food safety procedures.